-

CALL US

+91 9787000446 / +91 7358300446

-

MAIL US

enquiry@inconexim.com

- WE ARE MERMBER OF

CALL US

+91 9787000446 / +91 7358300446

MAIL US

enquiry@inconexim.com

Coir pith is also known as coco pith, or cocopeat is the binding material that comes from the fibre portion of the husk. It is a by-product of extracting coir fibre from the husk of a coconut. Brown coir pith comes from ripe, mature coconuts, while younger, immature coconuts produce white coir pith.

INCON EXIM is the largest Suppliers and Exporters of Coco Peat in India. We are supplying the best quality of coco peat at very competitive prices for our clients. Our main aim is to reach the best quality product with proper packing and on time delivery to our valuable clients.

We at INCON EXIM, procure 100% natural and organic coir products suitable for horticulture, floriculture, substrates, plant/animal bedding, upholstery, furniture, industrial absorbents and scrubbers. Our coconut peat can be used as a growing medium for various nurseries, hydroponic crops, plant propagation, mushroom farming and bedding plants. Open grow bags, Grow bag slabs, cocopeat pellets, Etc.,

The coir dust is washed, heat treated, screened and graded before being processed into various Cocopeat products for horticultural/agricultural applications and as industrial absorbent. The compressed cocopeat is converted into fluffy cocopeat by adding water. One kilogram of compressed cocopeat will expand to 15 litres of moist cocopeat. The Cocopeat by itself does not have any nutrients for plant growth. Necessary nutrients will have to be added according to the plant that is to be grown exclusively in cocopeat.

Cocopeat is also mixed with sand, compost and fertilizer to make good quality potting soil. In horticulture, cocopeat is recommended as substitute for peat because it is free from bacterial and fungal spores and is produced without any environmental damage caused by peat mining. Being a good absorbent, dry cocopeat can be used as an oil absorbent on slippery floors. Cocopeat is also used as bedding in animal farms, poultry farms and pet houses to absorb animal waste so as to keep the farm clean and dry.

| Size of bale | 30 x 30 x 15 cm |

|---|---|

| Weight per bale | 4.5 kgs to 5 kgs. |

| Volume | 68-80 Litres. |

| Compression Ratio | 5: 1 |

| Size of briquette | 20 x 10 x 6 CMS |

|---|---|

| Weight of briquette | 650 grams |

| Volume | 10 to 11 Litres |

| Compression Ratio | 8: 1 |

| Bale of 5 kg. | 22 M. tones or 4400 Bales |

|---|---|

| Briquette of 650 grams | 24 M. tones or 36,500 Briquettes |

100% organic

High water and nutrition holding capacity

Enhance strong and healthy root system

Good air porosity

Perfect growing medium for plants

Used in Tomato, Cucumber, Rose, Gerbera, and Strawberry plantation.

Used in Horticulture and Floriculture Environments

Used in green house plantation

Cocopeat is a multipurpose growing medium that provides new opportunities for: Potting Mix Suppliers, Seedling Nurseries, Hydroponics Growers and Golf Green Constructors.

Cocopeat provides as an organic alternate to rockwool and perlite media without the environmental disposal issues. Hydroponics crop production using Cocopeat makes the opportunity to consistently maximize yield and provide better quality.

Excellent water holding capacity of cocopeat provides a buffer in high temperatures and high crop load demand without compromising air supply. Additionally, it offers high water absorption and retention rate.

The presence of organic compounds in Cocopeat can results strong root growth compare with other growing medium. In addition, it offers some natural resistance to plant diseases, so the plant live span will be long.

Soil quality plays a key role in the making of home gardens, Terrace gardens, Lawns, Nurseries as well as in Horticulture and Floriculture. Factors like salinity and less water holding capacity make soil unsuitable for cultivation. Coir pith is an ideal soil re-conditioner, soil structure improver and soil substrate with excellent water holding capacity. India annually produces about 280,000 metric tons of coir fiber. By weight, coir fibers account for about one-third of the coconut pulp and the other two-thirds is the coir pith.

Coir pith is also known as coco pith, or cocopeat is the binding material that comes from the fibre portion of the husk. It is a by-product of extracting coir fibre from the husk of a coconut. Brown coir pith comes from ripe, mature coconuts, while younger, immature coconuts produce white coir pith.

INCON EXIM is the largest Suppliers and Exporters of Coco Peat in India. We are supplying the best quality of coco peat at very competitive prices for our clients. Our main aim is to reach the best quality product with proper packing and on time delivery to our valuable clients.

We at INCON EXIM, procure 100% natural and organic coir products suitable for horticulture, floriculture, substrates, plant/animal bedding, upholstery, furniture, industrial absorbents and scrubbers. Our coconut peat can be used as a growing medium for various nurseries, hydroponic crops, plant propagation, mushroom farming and bedding plants. Open grow bags, Grow bag slabs, cocopeat pellets, Etc.,

The coir dust is washed, heat treated, screened and graded before being processed into various Cocopeat products for horticultural/agricultural applications and as industrial absorbent. The compressed cocopeat is converted into fluffy cocopeat by adding water. One kilogram of compressed cocopeat will expand to 15 litres of moist cocopeat. The Cocopeat by itself does not have any nutrients for plant growth. Necessary nutrients will have to be added according to the plant that is to be grown exclusively in cocopeat.

Cocopeat is also mixed with sand, compost and fertilizer to make good quality potting soil. In horticulture, cocopeat is recommended as substitute for peat because it is free from bacterial and fungal spores and is produced without any environmental damage caused by peat mining. Being a good absorbent, dry cocopeat can be used as an oil absorbent on slippery floors. Cocopeat is also used as bedding in animal farms, poultry farms and pet houses to absorb animal waste so as to keep the farm clean and dry.

| Size of bale | 30 x 30 x 15 cm |

|---|---|

| Weight per bale | 4.5 kgs to 5 kgs. |

| Volume | 68-80 Litres. |

| Compression Ratio | 5: 1 |

| Size of briquette | 20 x 10 x 6 CMS |

|---|---|

| Weight of briquette | 650 grams |

| Volume | 10 to 11 Litres |

| Compression Ratio | 8: 1 |

| Bale of 5 kg. | 22 M. tones or 4400 Bales |

|---|---|

| Briquette of 650 grams | 24 M. tones or 36,500 Briquettes |

100% organic

High water and nutrition holding capacity

Enhance strong and healthy root system

Good air porosity

Perfect growing medium for plants

Used in Tomato, Cucumber, Rose, Gerbera, and Strawberry plantation.

Used in Horticulture and Floriculture Environments

Used in green house plantation

Cocopeat is a multipurpose growing medium that provides new opportunities for: Potting Mix Suppliers, Seedling Nurseries, Hydroponics Growers and Golf Green Constructors.

Cocopeat provides as an organic alternate to rockwool and perlite media without the environmental disposal issues. Hydroponics crop production using Cocopeat makes the opportunity to consistently maximize yield and provide better quality.

Excellent water holding capacity of cocopeat provides a buffer in high temperatures and high crop load demand without compromising air supply. Additionally, it offers high water absorption and retention rate.

The presence of organic compounds in Cocopeat can results strong root growth compare with other growing medium. In addition, it offers some natural resistance to plant diseases, so the plant live span will be long.

Soil quality plays a key role in the making of home gardens, Terrace gardens, Lawns, Nurseries as well as in Horticulture and Floriculture. Factors like salinity and less water holding capacity make soil unsuitable for cultivation. Coir pith is an ideal soil re-conditioner, soil structure improver and soil substrate with excellent water holding capacity. India annually produces about 280,000 metric tons of coir fiber. By weight, coir fibers account for about one-third of the coconut pulp and the other two-thirds is the coir pith.

India has made unmatched progress in coconut cultivation in the last few years and now it has become one of the leading countries in coconut production and productivity.

Coconut is a multipurpose fruit with high economic value. coconut is celebrated as a symbol of prosperity, a blessing of nature, an auspicious object of ceremony, a useful item of handicraft, and an essential ingredient for cooking.

Coconut has a special place in the culture of India. It is believed to be an auspicious fruit and used in many rituals on pious occasion. Coconut is offered to deities in temples across the globe.

We at INCON EXIM, precure the coconuts directly from the farmers and farm owners to maintain quality standards and to meet out to the competitive price. We have a separate team to carefully handle the customer requirements and they see to that the right products reach our valuable customer in right stipulated time.

Our coconuts are fluttered in 55 to 65 days from coconut trees. We store around 50000 to 60000 coconuts for one lot, after 30 to 35 days we peel hush covered with 3 eyes of coconuts. We are keeping this method to increase coconut's self-life for 45 to 65 days at any weather of world. Later the coconuts are sorted accordingly and well packed by experienced people based on our customer needed weights and expects. We are packing polypropylene bags, cotton box and net bags as based on customer requirements.

INCON EXIM can supply fresh coconuts of Indian origin for any demanded quantity at a competitive rate regularly. We are well known for whole sale suppliers and exporters of fresh coconuts and coconut products. The Company have all grades of coconuts in all maturities, we can supply to various parts of India as well as abroad. The Company can supply up to One million coconuts per month. The Company have also high-quality export coconuts of circumference 12 to 15 inches and above

| Fresh Coconut All Above | 500 to 550 grams |

|---|---|

| Fresh Coconut Circumference All | 12 to 15 inches |

| Colour | Export Brown Colour Coconut |

| Origin | INDIA |

| Fresh Coconut Numbers per Bag | 25 nuts /15 and 15.5 kg per bag |

| Self-Life | 55 to 65 days |

| Load ability | 40 feet – 45000 pieces in 1850 bags |

| Port | Sea – Tuticorin / Chennai / Cochin |

We invite the local buyers from all over India. We provide different sizes of coconuts. Our complete range is extensively acclaimed in the domestic market for its high nutritional content, longer shelf life and purity. Further, we use finest quality packaging material to pack this range to ensure their freshness and quality remains intact. We are looking Overseas queries.

INCON EXIM have gained a reputable position in the field of supplying and exporting a wide array of Coconut Products due to our strict adherence to Total Quality Management Policies. The export quality coconut offered by us has a shelf-life guarantee of more than 50 days, our coconut is well said loud for its taste and its aroma. These coconuts are procured from the reputed vendors of the industry, who possess rich experience in this field. Further, our quality analysts test the range on varied quality parameters at our in-house quality testing unit to ensure its premium quality. The packaging of these coconut products is done with utmost care under the strict supervision of our experienced packaging staff to make sure that they remain unbroken and safe during the transit period.

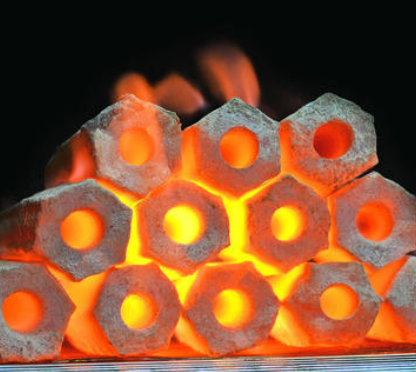

Coconuts have long been a source of a cool and refreshing drink that can be enjoyed throughout the year. But now this humble fruit is finding use in a variety of industries in a very different form – as activated carbon. Activated carbon is manufactured from various organic substances with a high carbon content, the most popular being coconut husks. Activated carbon finds use across sectors - from air and water purification to gold mining and air masks. It is its unique adsorbing power that drives its demand and is produced from carbonaceous materials such as coconut husks, various types of pith, jute, wood, etcGlobally, the export of activated carbon is expected to grow in the coming years.

INCON EXIM is one among the leading supplier and exporter of Coconut Charcoal to domestic and international markets. Owing to our dedication in customer service and fair pricing methods, we have earned the trust of industrial customers in the short period of time in the business. Our company motto has always been timely service and the right quality. We are one among the well-recognized supplier of Charcoal in Tamil Nadu, India.

Our filtering and charcoal treatment process ensures the highest quality, clean and long-burning charcoal. You get the first-grade charcoal at all times as we hand select the charcoal.

Our charcoals, which are produced from renewable hardwood, have excellent burning qualities. Moreover, it does not spit, spark, or emit much smoke. It has low ash content.

On the other hand, it has high density, offers better heating and burns for a long time.

It can be easily stored.

Our charcoal dries quickly and has a low moisture content.

Activated carbon from coconut shells is produced using steam. According to Coconut Development Board, converting a coconut shell into activated carbon is a two-part process. First, the coconut shell is converted into charcoal through a carbonisation process.The charcoal is then introduced to steam at a high temperature of around 900-1100 Celsius in order to activate the carbon and increase its adsorption capability.

As of now, there are three main types of activated carbon that are available in the market: granulated, powdered or in the form of pellets. The granulated and powdered forms of activated carbon are the more popular forms and in the recent times the global demand for active carbon is being driven by an increase in consumption of the powdered variety,according to a report the demand for powdered activated carbon comes from pharma and filtration industries where it’s used for decolourisation and deodorization. Overall US, Japan and Germany are the largest importers of the product. US, followed by South Korea, UK and Russia were the biggest buyers of activated carbon from India.

Activated Carbon produced from our coconut shell has certain specific advantages as the raw material can adsorb certain molecules and because of its density retains good strength and physical properties. Our Coconut Shell is carbonized by using destructive distillation process which produces a very superior product. Our shell charcoal is manufactured by processing shells of fully matured nuts in a modern carbonisation reactor wherein the process is clean and has a carbon negative.

We offer an Optimum quality coconut shell charcoal which is in huge demand in the Global Market. We are using fully dried, clean, matured coconut shells to obtain Good Quality Charcoal.

Good Absorption Performance.

High Strength

Long Service Time

Good Service.

All the above are some of the features of our charcoal. Our charcoal production is thoroughly supervised in order to get the finest quality. These coconut shell charcoals are available at industrial leading price. If you are interested contact us for SPECIFICATIONS and SGS LAB REPORT .

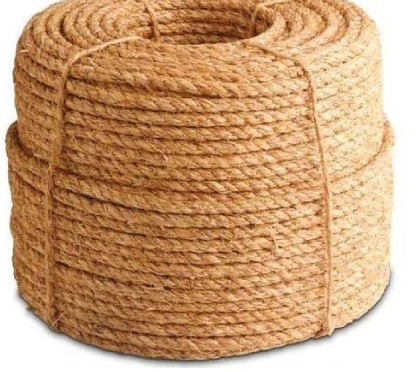

The application and uses of coconut fibre have very long history, ancient navigators widely use these coconut fibre-based ropes for their ships over long period.

Coconut fibre-based products was introduced to western world in late 19th century and now it’s a huge industry which creates lots of other product. Since coconut fibre is 100 % natural product this is recyclable green products. Most of coconut fibre extracted out of coconut husks is 4 to 12 inches in long and they coloured brown and white naturally.

India is the largest coconut fibre producing country in the world and more than 90% of coconut fibre are exported from India to the world market. There are so many countries which produce coconut fibre but India is well-recognized to produce best coir in the world.

INCON EXIM is proud to be identified as an organization consistently reaching out to markets around the globe through its unique blend of a remarkably international outlook along with an innately Indian sensibility.

In our process of manufacturing, we do not use chemical washes and steaming that destroy naturally occurring benefits in coco coir. Our final products are super washed with clean fresh water to bring very low level of salts and EC. Once coco coir meets our strict standards and analytical requirements, it is dried, compressed and packaged. We make sure to offer the highest quality coconut coir growing medium substrates in the market.

Our aim is to deliver goods of high quality at low costs and also to ensure that our clients remain abreast of the latest market trends, in recognition of our continuous commitment to achieving total customer satisfaction.

| Packing | hydraulically compressed & tightly strapped bale |

|---|---|

| Bale weight | 100 kg - 125 kg/bale |

| Load ability | 180 – 200 bales/40 ft. container (approximately 20mt) |

There are various types of coconut coir in the market and the most popular fibre types are.

Brown fibre

White fibre

Bristle Coir

Buffering Coir

| Fibre colour | White/Brown/Golden Brown |

|---|---|

| Length | >10 CMS |

| Moisture content | < 15% |

| Impurity | < 3% |

| Packing | Tightly Strapped Bales |

| Quantity | 1x 40’ HC (17-18 metric tons) |

Coconut fibre is extract out of coconut husk through a process which named as retting in coconut industry and the coconut husks soaked in water for over a long period and the Coir is removed from the coconut husks and by considering the colour and size it’s graded and used for different purpose. Sometimes different coconut fibre machines are used to produce coconut coir in coconut husks soak process.

The most traditional uses of coconut coir are to making ropes and mats but recent development coconut coir is now used for wide range of applications. Following are some of the popular applications of coconut fibre in modern-day.

For create ropes by use of Coconut Fibre

Use for Insulation in construction and other industry

Mattresses (very popular home product)

Irrigation Industry

Shock absorbent in Transport industry

Vehicle seats (Automobile Industry)

Landscaping (substitute for traditional soil-based peat)

Production of Concrete fibreboard

To Create Brushes for home use

To Create Brooms for home use

Soil Erosion Control Purposes

Upholsters padding for automobile sector.

To Create Furniture

Normally coconut fibre takes 20 years to decompose but this does not generate any harm for our environment. So, using product by use of natural coconut fibre is also good for our environment also.Most of coconut fibre-based products are tough and got great durability.

So, if you want to buy some items which use coconut fibre as raw material the above details would be more value for you.overall coconut fibre is multipurpose product which the applications spread around wide area.

Coir geotextiles are made from coconut fibre extracted from the husk of coconut. Like otherpolymeric counterparts, coir geotextiles are developed for specific application in civil engineering like erosion control, ground improvement, filtration, drainage, river bank protection, road pavements, slope stability etc. This biodegradable and environment friendly material are virtually irreplaceable by any of the modern synthetic substitutes.

INCON EXIM brings to our clients a wholesome and sturdy range of Geotextile that are available in various colours and lengths to suit the requirement of the clients. These are used in controlling landslides and soil erosion and usually laid along the river embankments, sides, canal banks and hill slopes. So, we take utmost care and we double check the quality to not to make any technical mistake. These are a range of woven open mesh fabrics made from 100% natural and biodegradable coir. These natural nettings hold the soil and seed intact during the establishment of vegetative cover. As it biodegrades it add organic nutrients to the soil. Coir Geotextiles are "eco-friendly" products.

INCON EXIM claims to be the largest exporter and supplier of Geotextile product both in domestic and international markets, our team makes sure that the product requested by our valuable clients reaches them promptly without any flaws, customer satisfaction is given the utmost priority than anything else, we hope this attitude is driven us towards success.

1. Retting the coconut husks, which means soaking in water for 8-10 months to remove certainnatural chemicals from the husk to enable proper defibring.

2. Extraction of fibre either manually or with the help of a machine.

3. Spinning of yarn.

4. Weaving to obtain the desired geotextiles.

Modern day practices have speeded up the process for retting with agents and the fibre isextracted mechanically.

How it is being laid is, first selecting the type of coir geotextiles from site assessment, formingthe required gradient, anchoring and laying the geotextiles in rolls or grids, in the direction of water flow, trenching the bottom portions, placing the seedlings of required plant species with necessary fertilizer and irrigating the laid area. Rolls of the coir matting were first anchored firmly in the trench and then unrolled along the slope. A minimum overlap of 15 cm is given between adjacent ones. Anchoring of the matting was with mild steel staples spaced to form 2m grids. If the soil is organic, additional fertilizers are not necessary.

Geotextiles give maximum protection to the soil beneath until the grass takes root and provide permanent vegetation. After the soil is thus stabilized, the netting decomposes and provides nourishment to the grass growing in the soil.

Erosion Control

Rainwater Harvesting

Stabilization of embankment

Canal Bund Protection

River Bank Protection/Seashore Protection

Coastal protection using geotextiles

Reinforcement

Road Pavements

Ground Improvement

Tests conducted showed that natural fibre like cotton degrades in six weeks, jute in eight weeks,coir still retained 20% of its strength even after one year.Coir geotextiles are used extensively in various applications successfully in various countries.Coir industry in India supports around half a million people belonging to weaker sections in the ruralpopulation. Wide use of this material will be a promise to the coir industry.

Coconut shell, a once discarded outer hard cover of a coconut is now a product of great demand.Coconut shell is the toughest component covered in the coconut fruit. It is situated between the flesh and husk. Coconut shell is widely used for making handicrafts and other applications. Many handmade decorative products are produces using coconut shell because of its strength. Also, they are used to produce charcoal. The traditional pit method of production has a charcoal yield of 25–30% of the dry weight of shells used.

We at INCON EXIM, offer high quality Coconut Shell at an affordable cost, each shell is processed and quality checked for clean cut and customer preferred sizes. We follow strict quality policy to ensure that the best is delivered to our customers. Our company knows that quality and business ethics is very important in gaining success in export business.

We at INCON EXIM recycle coconut shells that have been discarded as waste, give them a little love and turn them into beautiful eco-friendly products, they’re handcrafted, 100% natural and made entirely from organic coconuts.

We are professionals with more than fifteen years of experience in this industry. Our team is hard working, dedicated, and honest to deliver the best product to our valuable customers. INCON EXIM is proud to have named one of the largest exporter and supplier of coconut shell and other coco products to both domestic and international markets.

In addition to the known fact that coconut shells are used in handicraft industry to make very interesting pieces of art, coconut shells have various other uses apart from the arts and crafts industry. Theythrow light on such innovative products derived from this humble outer shell. The coconut shell has a high calorific value of 20.8MJ/kg and can be used to produce steam, energy-rich gases, bio-oil, biochar etc.

Coconut shell powder is used extensively in the manufacturing of mosquito coils and incense sticks. It is also used in plywood manufacturing as a phenolic extruder and as filler in the manufacturing of resin glue. It has uniform quality and good resistance to water and fungal attacks. Good quality coconut shell powder is obtained by using matured coconut shells and appropriate machinery.

Coconut shells have been widely used to package coconut flavoured ice cream in several European countries. The hardened shell of mature coconuts is horizontally or vertically cut with high-speed blades and the inner and outer surfaces are polished to give a smooth finish. Coconut shells varying volumetric capacity ranging from 185 ml to 200 ml are packaged in corrugated boxes complying with EU standards. Some common products made out of coconut shell are:

Coconut Cups

Coconut Shell Pot Plant

Coconut Shell Craft Lamps

Coconut Shell Jewellery

Coconut Shell Painting

Coconut Shell furniture

Coconut Shell Spoons and Forks

Coconut Shell Bowls

Our daily-use, basic products made out of coconuts which are not only eco-friendly but are also lightweight yet durable and attractive. Due to increased awareness among people about using green, sustainable products and reducing the use of plastic products, our handicraft artists and our manufacturing vendors are creating beautifully designed coconut shell products like coconut shell furniture, coconut shell keychains, coconut shell cutlery, and much more at affordable prices.

Coconut water is never out of trend despite various attractive aromatic and nutritious drinks in the market. It is a miraculous drink beneficial for our body in multiple ways. Coconut water has been consumed for centuries in tropical regions around the world. In Ayurveda, Coconut water is believed to help in activities of the body such as digestion and urination. It helps to provide an instant boost of energy.

INCON EXIM is one of the leading exporters and suppliers of Tender Coconut in India to the global market with best quality which meets international standards. Tender Coconuts are consumed largely in the summer season for their cooling properties and as a natural drink. This offers all the nourishment and the goodness of nature to a person, and the supplement drink has vitamins B and C along with minerals to provide energy for the whole day. It is a natural substitute for glucose.

INCON EXIM have gained a reputable position in the field of supplying and exporting a wide array of Coconut Products due to our strict adherence to Total Quality Management Policies. The export quality coconut offered by us has a shelf-life guarantee of more than 50 days, our coconut is well said loud for its taste and its aroma. These coconuts are procured from the reputed vendors of the industry, who possess rich experience in this field. Further, our quality analysts test the range on varied quality parameters at our in-house quality testing unit to ensure its premium quality. The packaging of these coconut products is done with utmost care under the strict supervision of our experienced packaging staff to make sure that they remain unbroken and safe during the transit period.

Coconut water is a clear liquid present inside of green Coconuts. Over 95% of Coconut water is water. An average green Coconut provides about 0.5–1 cups of Coconut water.

Coconut water is rich in various minerals and electrolytes like potassium, calcium, manganese, antioxidants, amino acids and cytokinin. Coconut water is the best source of potassium and contains almost 470 mg of potassium. It is low in calories, carbohydrates, sugar, unlike other juices.

Energy booster

Best alternatives for sugary juices

Helps to lose weight

May benefit to manage diabetes

May be beneficial for heart health

May help to reduce high blood pressure

Help in good digestion

May help to detox the body

May help to prevent kidney stones

May prevent urinary tract infection

May reduce fatigue and stress